Common Trouble Shooting Issues with a Flymo Corded Lawnmower

Flymo Corded Lawnmower TroubleShooting

Over time with general usage, improper operation and storage can deteriorate your machine, causing your lawnmower to develop issues. Before using, you may want to read over the manual to understand your machine more, taking advice from the manufacturer to extend the life of the lawnmower.

Here is a breakdown guide, pinpointing common faults that can occur when you have had a lot of usage out of your corded Flymo Lawnmower.

For the Venturer 32, Visimo, Rollermo, Easimo and RE 320, Chevron 32- Chevron 37VC

Failing to Operate:

- Are you following the correct starting procedure?

Check your manufacturing guide for the correct starting procedure for your model.

- Is the power turned on?

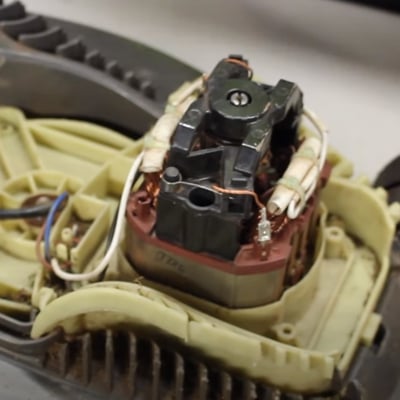

Check the lawnmower propulsion system is working. Additionally, inspect that the cable isn’t coming out of the socket if there is damage to the cable or has a blown fuse.

- Check the fuse in the plug

You can find out if the fuse has blown using a multimeter, then replace if required.

- Fuse continues to blow

If this continues to happen, you will need to take your machine to a specialist to be checked over.

- Grass box is full

Check that box hasn't been overloaded - Some lawn mowers cut out when the grass box is full. Simply empty the grass box.

Poor Grass Collection:

- Cutting Long Grass

Cutting too much grass or grass that is too long can cause the mower to slow down and even stop. To resolve the problem, raise the cutting height and recut it afterwards with a lowered height. Alternatively, you could use a brushcutter if the grass is too long, then go over the grass with your lawnmower with an adjusted cutting height.

Excessive Vibration:

- Worn or Damaged Blade

Disconnect from the mains, and check that the blade has been fitted properly. If this part is damaged or worn, replace. When replacing or sharpening, make sure that the blade is perfectly balanced. If it is not, this can cause an uneven cut and cause irreparable damage to the machine.

Lawnmower becomes heavy to push:

- Grass too long or uneven ground

The cutting height should be raised to a higher position.

- Check that the wheels and rollers can move freely

The wheels and rollers should be able to rotate freely to easily push the lawnmower.

Lawnmower is slowing down:

- Removing Debris

Overtime debris can build up underneath with grass and soil. Therefore, this needs to be cleaned out to ensure that your lawn mower can work to its full capacity and so that the blade can function properly.

- Check the Drive Belt

There is a possibility that the drive belt has worn or even stretched, which will mean the blade will not rotate properly. Check that the bearings on the spindles as this can hinder the mower's performance.

- Blade not Rotating

If the motor is running and the blade is not turning, the belt could be loose or even have snapped. In this case, make sure the four screws that tighten the belt are secure. Or if the belt has snapped, replace this part.

If you still have persistent issues with your lawnmower this will then need to be dealt with by a professional.