Common Chainsaw Issues

Chainsaws require regular maintenance and servicing to keep them in their best condition in order for your cutting jobs to be done quickly and safely.

When completing any work on your chainsaw we recommend referring back to your owners manual you will have received when purchasing your chainsaw. Alternatively, if you are unsure we recommend taking your chainsaw to a repair centre.

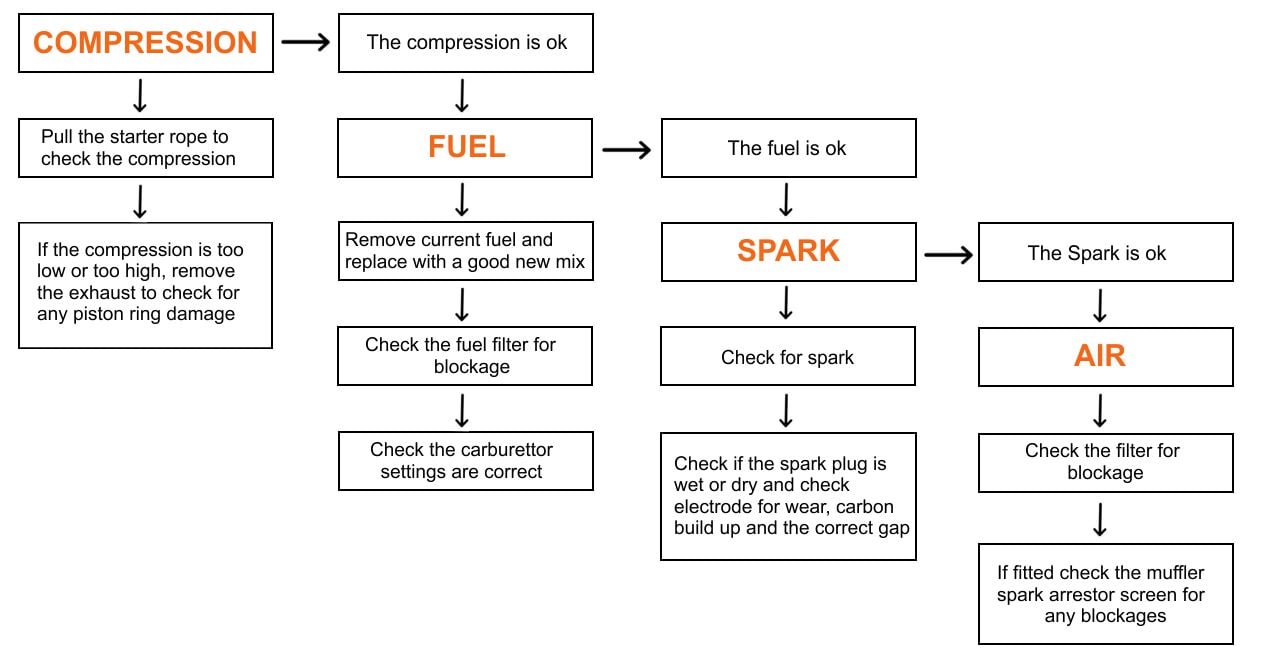

Basic Checks

Checking the Fuel Supply

There are a couple of fuel-related checks to be completed: ensure you have checked the fuel mix itself, blockages or cracked lines and the chainsaws carburettor settings.

Firstly, empty the fuel tank and replace it with a good quality fuel mix. If your chainsaw has been standing for a long period of time in the fuel tank, it may be contaminated. We have a guide on how to work out the correct two-stroke mix ratio here.

If there are any blockages such as in the fuel filter, you may find a fuel system cleaner can help. The fuel system cleaner is added to the fuel tank and left to sit for several hours. Once this has settled, you will need to start the engine in order for the fuel system cleaner to circulate evenly throughout the engine, this will help remove any blockages in the chainsaw.

The fuel filter helps feed fuel into the engine from the fuel tank. It connects to the internal fuel line, preventing wood chips, oil and dirt from contaminating the fuel. The fuel line is connected to the carburettor (found near the throttle towards the rear of your chainsaw). Check this fuel line to make sure it isn’t cracked or broken, as they can become brittle with age.

The fuel filter is connected to the fuel line, you will need to pull out a little of the fuel line to expose it (ensure you don’t pull it too hard). If the fuel filter is damaged or blocked, it can be removed and replaced with a new filter. Simply pull off the old filter, twist on the new one and feed it back into the chainsaw housing.

Checking the Air Flow

If the air filter is blocked, we recommend you replace it. The filter stops airborne contaminants from entering the chainsaw combustion chamber. Ensure you use your user manual to locate the filter and check it for build up.

You should also check the muffler while doing these checks, use compressed air to remove any excess carbon deposits once it’s been removed from the engine. Once you have checked this, check the muffler spark arrestor screen. This prevents the muffler from combusting, make sure it’s clean and free from debris build up to help prevent this.

Finally, check all the hoses and gaskets to ensure they haven’t become loose.

Checking for Spark

Without a spark the fuel will be unable to ignite, meaning the chainsaw will not start. To check your spark plug, locate it and remove the cover and the spark plug from the cylinder, while attaching the spark plug wire to it. Do not put the spark plug back into the cylinder! Touch the spark plugs electrode tip to a metal surface on the engine and pull the starter cord. If you are able to see sparks, the spark plug is working. However, if you do not see the spark, then check the spark plugs electrode for any carbon build up, damage or general wear as well as the correct gap spacing. Check the spark plug has had a good clean with a damp cloth, allow it to dry, then test again.

If you find you’re still having difficulties, but the spark plug is still producing a spark, check the gap. The spark plug gap is an air gap between the ground electrode and the centre electrode. If the gap is too small, the spark will struggle to ignite the fuel and air mixture. If the gap is too large, it makes it difficult for the spark to bridge the gap.

Over time, the electrodes wear away due to the constant arcing of sparks, this can lead to the gap becoming larger, which may result in difficulties with starting your chainsaw. If the gap looks too large, we recommend replacing your spark plug.

Setting a chainsaw carburettor

The next thing to check is the carburettor. To check this, place the chainsaw on a sturdy and even surface, start your chainsaw and let it warm up for a couple of minutes or so. Next to the pull rope on the body of the chainsaw you will find three different adjustment screws. Each screw will have a letter stamped next to it.

The adjustment screws work fine by turning the carburettor. The letters on the screws represent High (H), Low (L) and Idle (T). The H screw regulates the Air/ Fuel mix during high RPMs, the L screw does the same during low RPMs. The T screw regulates how much fuel is sent to the carburettor while idling until the throttle is pressed.

L Screw - With the chainsaw still running, get a screwdriver and turn the L screw clockwise. Keep turning it until the engine almost stops turning. Then, slowly turn the adjustment screw counter clockwise until you hear the engine idling smoothly. Rev the engine, you’re checking for a smooth and responsive rev up. Keep making fine adjustments to the L screw until the engine accelerates smoothly.

T Screw - The T screw is the adjustment screw responsible for adjusting the chainsaws idle. Start by turning the screw clockwise until the chainsaw begins to move. Once you notice it moving, turn the T screw counterclockwise slowly until the chain stops. The engine should continue to idle smoothly without the chain moving around the chain bar.

H Screw - Finally, turn the H screw counterclockwise until it comes to a natural stop (ensure you do not force it past this point). You will notice the engine will sound rough. Then turn the H screw clockwise until the engine sounds smooth. Give the throttle trigger a little squeeze, ensure there is no smoke from the exhaust and the engine should accelerate with ease!

Compression issues

If you have checked the above and find your chainsaw is not starting when you pull the starter rope, you could have an issue with the compression. Compression is generated by the engine via the crankcase and combustion chamber. You may experience decreased power or complete shutdown of the engine if the compression is too low.

To check for low compression, place your chainsaw on the ground and use the starter rope to lift it. If the compression is good, it will prevent the rope from pulling out. Carefully lift the weight of the chainsaw by the starting cord. However, if you notice the rope slowly extending, the chainsaw compression is more than likely to be low.

An air leak may occur on the crankshaft seals. Damage to the piston or the piston rings may also be caused by the compression. The piston rings contain cycle pressures, this ensures the force from the combustion is spent pushing the piston down on the power stroke. If there is a leak, the cycle pressure can leak into the crankcase. This results in a lack of power of the engine not starting.

Copyright Notice: No copyright Infringement intended. Please note all information used is for informational use only. All copyright belongs to Husqvarna at: https://www.husqvarna.com/nz/forest/when-working/maintenance/common-chainsaw-problems-solved/