Guide for NGK Spark Plug Numbering System

NGK have been developing their spark plug technology since 1930 and are the leading manufacturer for spark plugs, that can be used for motorcycles, cars, horticulture and many other plant applications. NGK produces over 1000 different types of spark plug, ensuring they apply to even the most demanding manufacturers’ specifications.

NGK spark plugs have two codes that are associated with them. Firstly, there is the spark plug number which represents the specification of the spark plug. NGK spark plugs also have a NGK stock number. For example, the BPMR7A plug has a stock number of 4626. Both part codes can help you identify the correct part, but only one of them will give you information about the spark plug itself. NGK spark plug codes can be decoded to help identify the suitable replacement or equivalent for an application.

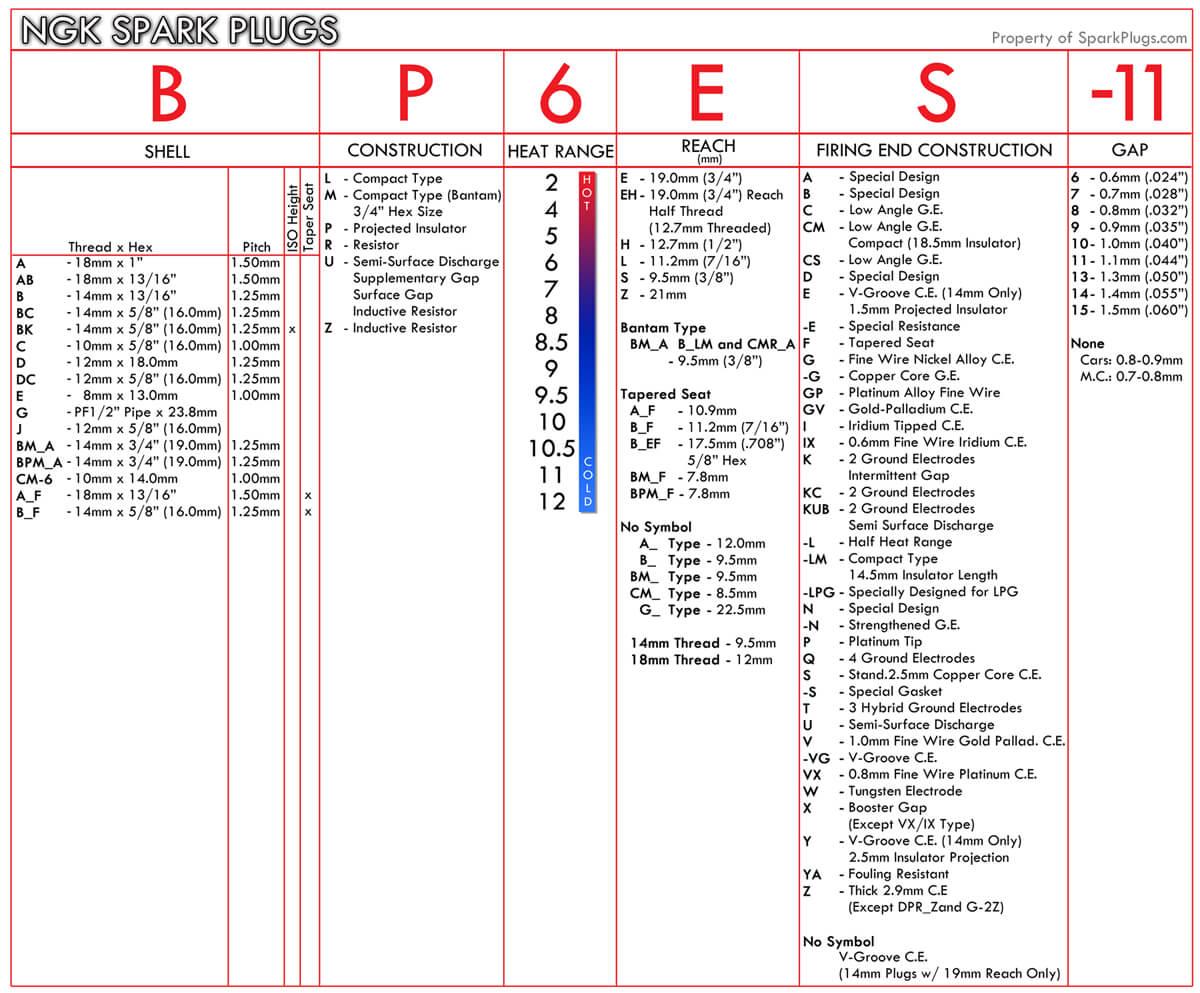

The first part of the part code denotes the shell, thread and pitch of the plug. The table above lists the most common or standard thread sizes. However, there may be more variations than shown here, that are specific to manufacturers’ applications.

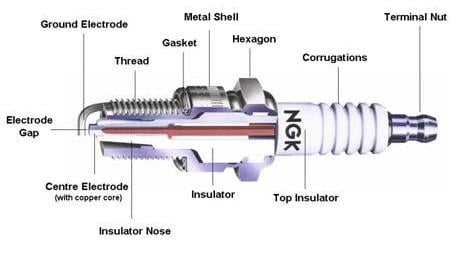

The pitch is the measurement between a pair of thread peaks. There may be thread exceptions for different models / machines. The thread reach is the measurement from the plug base to the end of the thread.

The first part of the part number also indicates when a spark plug has a tapered seat. The seat is the part that is fitted into the cylinder head of the engine. The types of seat for spark plugs are tapered / conical (no gasket or washer, contact direct with the cylinder head) and flat / gasket (gasket or washer seals between the plug and cylinder head).

This first part of the part number also indicates the hexagonal nut size that is used to loose/fix the spark plug. These are shown in the table in imperial & metric.

For example, we will use the BPR6ES to identify plug specifications. We can now see that 'B’' in BPR6ES specifies that the shell is 14mm x 13/16” & has a pitch of 1.25mm.

Secondly, we can figure out the construction of the spark plug from the second part of the part number. This part can be more than one letter, if the spark plug has more of the listed attributes. We can now see that ‘PR’ in BPR6ES specifies that the plug is a Projected Insulator and Resistor type.

The third part of the part number, which is the number, identifies the intended heat range. This is shown in an extending scale. 2 being the hottest and 12 being the coldest. So again, in the case of BPR6ES, the ‘6’ indicates it is suitable for mid range heat.

After the number, the next letter or letters identify the reach of the spark plug. The reach is distance between the point at which it runs out of thread at the metal shell and the ground electrode at the end of the spark plug. So ‘E’ in BPR6ES tells us that it has a 19mm (¾”) reach.

Next, we can identify the firing end construction of the plug. The 'tip' or 'firing end' specifies the projection of the central electrode, providing better and more efficient combustion. There are four categories of tip / firing end, which are listed below:

Recessed – Firing end within the shell, protection for racing engines, good vibration resistance.

Non projected – More or less level firing end with the end of threaded shell. Relatively short tip, provides good vibration resistance and good thermal conduction from the electrode tip.

Projected – Centre electrode and insulator extend from threaded shell, often 1.5mm. The tip is more exposed which produces a spark closer to the centre of the combustion chamber.

Extra projected – Similar to projected spark plugs, however these can be anything from 2.5mm to 10mm or even longer. These are often designed for specific machine applications. These are not recommended as they may cause damage to machines if not the correct application.

The terminal is the part where the plug cap is connected to the plug. Here are different types of terminals that NGK spark plugs use:

Removable – These terminals can be used with or without a terminal nut to provide connection to the plug cap. These may often cause electrical issues as it may be loose and may damage the plug if is too tight too.

Solid / fixed / post terminal – This terminal will have a fixed terminal nut which cannot be removed. If you attempt to remove you will damage your spark plug.

Threaded terminal – An exposed terminal thread.

Special / Stud – Terminals that do not fall under the other categories will be a special type of plug and often apply to certain models, such as miniature models and specific NGK plug designs.

In the case of BPR6ES, the ‘S’ determines a Standard 2.5mm Copper Core C.E.

Finally, sometimes a spark plug will have another digit at the end of the part number. This specifies the size of the gap that the plug requires. For example, the NGK spark plug BKR6E-11 will have a gap of 1.1mm (.044”).

Below is an example of the specifications of a spark plug that have been decoded to tell us what specific features this spark plug may include.