Back to

All Posts

Archives- March 2023

- November 2022

- October 2022

- July 2022

- June 2022

- May 2022

- March 2022

- December 2021

- November 2021

- October 2021

- August 2021

- May 2021

- April 2021

- February 2021

- January 2021

- November 2020

- September 2020

- August 2020

- July 2020

- June 2020

- April 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- April 2019

A Week Working with Villiers in the 1960's || Wyn Lees

A Week Working in Villiers Stores in the 1960's with Wyn Lees

In the 1960's, whilst working for Reliant Plant in Walsall Wood, I was invited to work a week in the Villiers warehouse. Reliant Plant was, at the time, Villiers main dealers in the Staffordshire Area. The warehouse was based in Upper Villiers Street/Marston Road in Wolverhampton. This experience was a real eye opener for me to see the sheer volume of spare parts and engines. I worked alongside Ted Cosgrove, the Stores Manager & his assistant John Tipton. Working to pull orders for the UK agents and overseeing customers. The warehouse was a hive of activity, full of large wooden packing cases, which stored Villiers C12 Engines. Each packed carefully with spare parts surrounding the engines to fill the cases, as these could be shipped to any where in the world.

The first personal computers didn't arrive until 1975, so as you can imagine a large warehouse would operate a little differently then it would today. On my visit in the 1960's there wasn't a computer of any kind in site, it was all paper systems. I remember two girls sitting together at a table, twins in fact, and their full time job was to hand write all the small tags and labels used for the parts. They would have to write the part number, quantity & location of the parts ordered by the customers.

During the week I remember pulling an order for piston rings. The order was for forty rings, and the bin I was pulling from contained packets of 100's. Can you guess what happened? I counted out the forty, and put the bag of sixty back in the bin (or so I thought.) I ended up mixing the bags up and giving the customer the sixty! The Foreman Checker soon found this mistake and gave me a good telling off!

One morning I was told to be on guard, the Major was coming round for his inspection. His name was Jack Flower, and I was told to address him as 'Sir' if he spoke to me. He was I recall a very tall upright flamboyant gentlemen with a regimental looking moustache. I was told he personally looked after the agents and stockists, which would involve a week away in the Channel Islands.

On a lunch time I was allowed, as a guest from Reliant Plant, the privilege of the sitting with other guests from distributors, stockists & dealers from around the country in the staff canteen. I was the first person to work in the stores, all the others were working in the engine rebuild section.

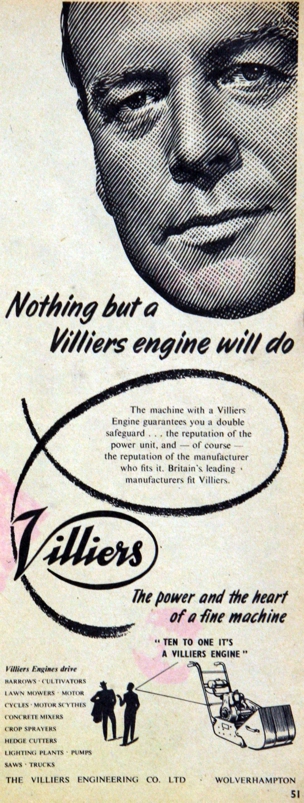

During my visit I was shown around the carburettor kitting workshop where hundreds of B10/1 carbs were made up to the different engine specs every day, and only twelve people worked in that department! Before I left I was also shown around the main manufacturing works, and what a sight. The machinery noises, the smell of work, the men and women who all helped these little Villiers industrial engines to be one of Great Britain's finest engineering products. It was and still to this day a privilege to have been involved.

- Wyn Lees

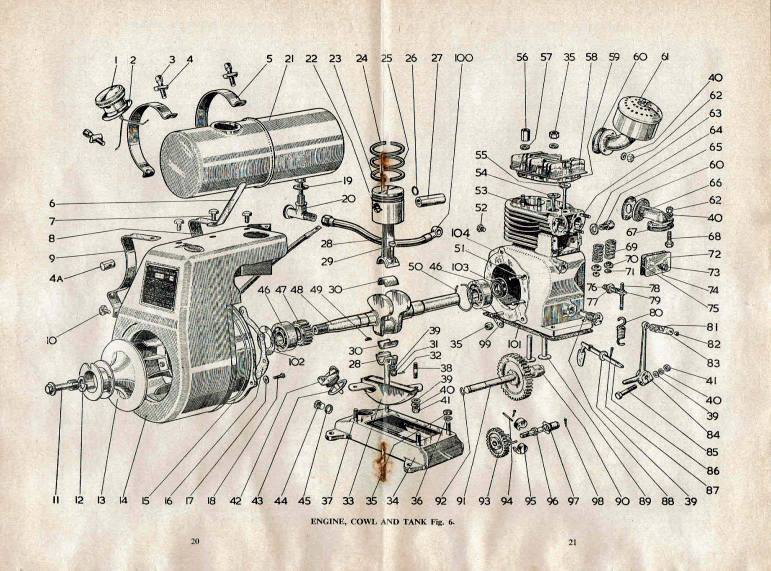

Villiers Mark 12 Engine, Operating Instructions & Spare Parts List (July 1957)

Visit our Vintage Engine Parts Section

Photo credit goes to www.gracesguide.co.uk, a great site for information on an encyclopedia of brands! Go check them out.