Back to

All Posts

Archives- March 2023

- November 2022

- October 2022

- July 2022

- June 2022

- May 2022

- March 2022

- December 2021

- November 2021

- October 2021

- August 2021

- May 2021

- April 2021

- February 2021

- January 2021

- November 2020

- September 2020

- August 2020

- July 2020

- June 2020

- April 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- April 2019

Petter Engines and Vintage Pumps || Petter Engines

Lubrication Pumps for Petter Engines

This week we're back at Hazel Lane, revisiting just how Alan & Wyn came to make Lubrication Pumps for Petter Engines. Lister & Petter Engines were the workhorse of the British Empire, known now as Lister Petter after combining in 1986. L&S are proud to still provide spares for some of the original Lister Petter Engines!

To set the scene, the Lamp House on the Hazel Lane Colliery Site was a challenging building to work in but this did not dampen Alan & Wyns enthusiasm to grow. As we have mentioned in our previous stories, the building was cold, draughty & bleak in the winters but the summers were good, and the work became more enjoyable. We continued to manufacture endless amounts of Water pump strainers, starting handles & jockey legs for trailers.

With Alan's continuing determination to never say 'no' to customers we took on a new project, a project that took our skills and machines to the next level. It was a precision part, a new exciting venture for us, introduced to us by Mr. Kelly who worked for Dandridge from Greenwich London, which was then part of the Hewden Stewart Group. The part? A Lubrication Pump that was to be fitted to the Petter Laboratory Engines (LAB1) These Pumps were used to test the various grades of oils, and how they would affect the wearing of parts on the engines, these were then supplied to oil companies around the world.

The testing was done by running the engines for 100 to 250 hours. They would then be stripped down in order to measure the wear on the parts created by the oil.

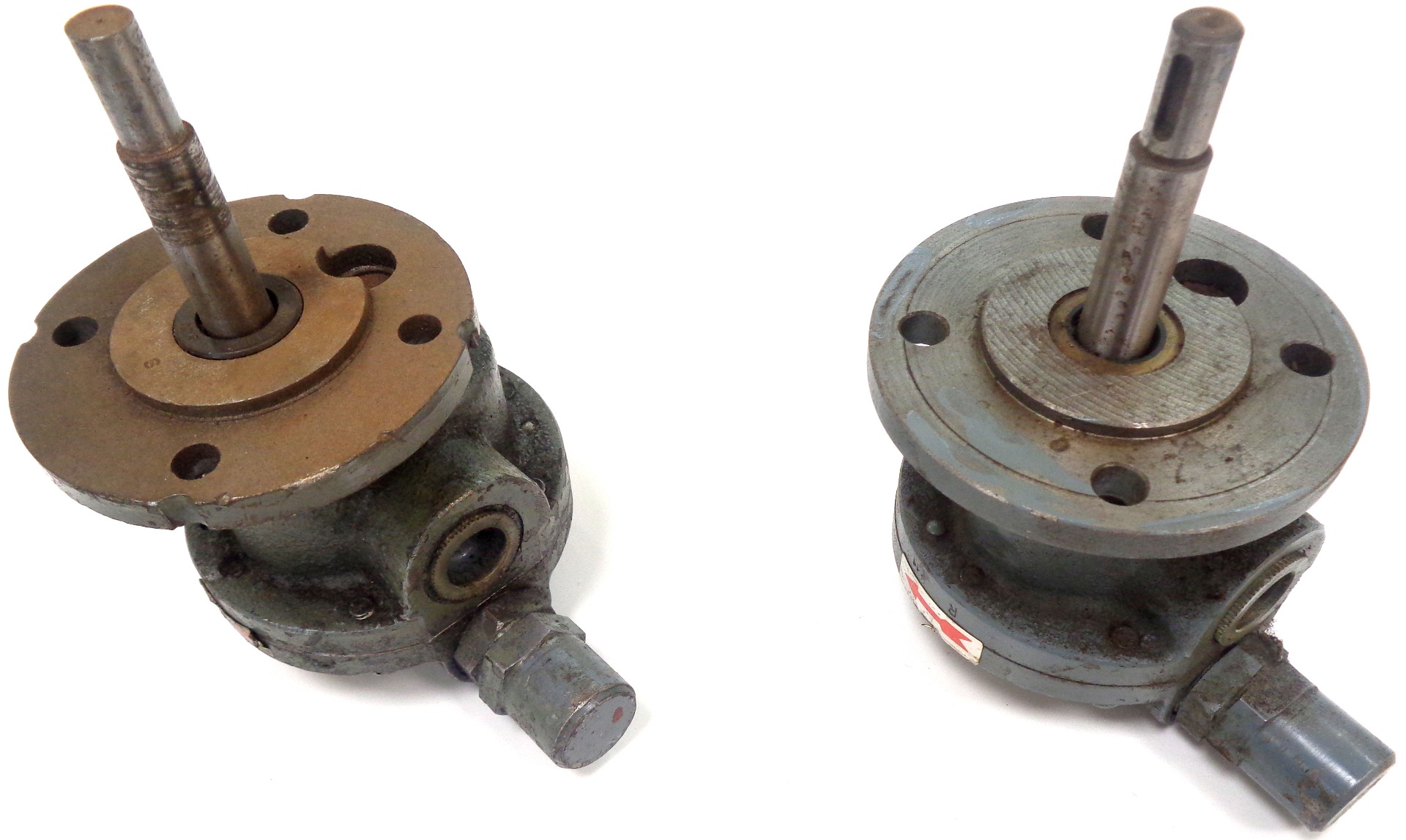

To manufacturing the pumps a drawing was supplied to us, however for small business' such as ours who would only be creating small batches of around 50 having individual castings to make the batches would have been uneconomical to produce. Instead we found a company in Stourbridge that supplied a standard oil pump to Cannon Industries from Birmingham. After buying these pumps we would strip them down, modify the casting and put in a new output shaft, which worked very well for this application.

I remember that we used to supply these for around £40.00 in the 1980's. Eventually after manufacturing these pumps for a while Mr. Kelly put Petters, from Staines Middlesex direct on to us, and we supplied them for years after. Through the years the process of making the pumps changes a lot, instead of doing the modifications ourselves we outsourced to a company in Germany that made the standard pumps, and they would do the alterations to Petter specifications, from the drawing we had received originally!

Here are a few pictures of part of the original Pump Casting we manufactured. If you are wondering why there are half circles surrounding the edge, you are not alone a lot of people have asked this question. These were created from the original holes in the standard pumps! We machined down the flange on the casting and re drilled hem in another position.

Don't forget to comment down below if you are enjoying our trips down memory lane! See you next time for another trip back in time, we have alot of interesting stories yet to come so keep your eye peeled.

Copyright Notice

Please note all images used under the fair use act, to inform not to sell of purposely reproduce. No copyright infringement intended. If you're interested in finding more about the W1 LAB engines please visit Agrimanuals as they have a fantastic original manual. The picture on this blog is taken from the front cover of this manual, and would have been the engine that Alan & Wyn had created parts for!